Before starting to talk about functional safety, it is essential to clarify some basic concepts. At this point comes the words safety and security in mind. I have observed in Turkey that these words are used in different contexts. However, I do not agree with this differentiation. For me safety and security have a common meaning: the state of being safe and a secure environment. They include and encompass each other. In short, we can call it both functional security and functional safety in Turkish without any loss in the meaning.

However, in order to understand “functional safety,” we need to focus on the differences between security and safety. Safety means to be inherently safe, while security means to be made secure from external dangers.

What is the Difference Between Security and Safety?

Imagine this: you have had an accident with your car. What would you do in such a situation? You would take safety/security precautions to bring yourself and the other vehicles into safety. You would wear a reflective safety vest, you would set up a warning sign at a 50 meters distance from your car and you would inform the police. So far what you have done is called “Security.” It means to take the necessary measures to maket he environment secure for yourself and the other vehicles (i.e. other drivers may not see you and crash your car). Safety implies making the system itself safe against the environmental risks caused by an inherent error.

Electrical and Electronic Devices, Systems and Security

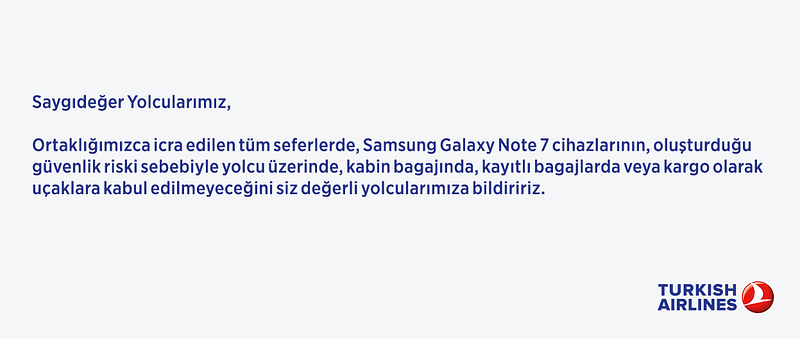

As consumers we expect a newly bought device, such as a cell phone or a TV, to function perfectly, not to break down and not to pose any risk sor dangers to us or our environment. This expectation is so natural that we are schocked when we encounter a break down or a risk. Let’s take the notorious exploding cellphone, Samsung’s Galaxy Note 7 Galacan example. The phone unexpectedly overheated and burnt. Eventually Samsung had to remove 2.5 million phones from the market and lost 5.3 billion dollars in stock value. This model was even banned from all airline flight because of the possible risks. Samsung disclosed that the problem occured because there wasn’t sufficient room around the heat-protective layer of the battery. One incident sufficed to discredit the biggest cellphone producer in the World and changed the entire company culture.

Almanya ve Avrupa’da tüm ürünler, çalışma ekipmanları ve görüntülenmesi gereken sistemler Product Safety Act’a göre üretilmek zorundadır. Buna EU tarafından hazırlanan European Directive 2001/95/EC temel teşkil eder. Her üye ülke kendi diline çevirmiştir. Bu normlara göre son tüketici için üretilmiş her ürün güvenli olmak zorundadır. Bu demektir ki her ürün öyle bir geliştirilmeli ve üretilmeli ki kullanıcıların sağlığını ve güvenliğini tehlikeye atmamalıdır.